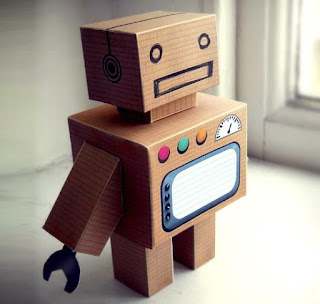

Structural engineering with cardboard

Moving into a new flat I have ended up with a lot of cardboard and have actually struggled to get it to all be taken away. I then saw this Kickstarter on hacker news which introduced me to the idea that I could perhaps use the cardboard I had been throwing away the whole time. I have been toying with some ideas for building myself a robot, or at least a robot arm but they seem to be just ludicrously expensive and still not able to lift much weight.

One of the problems with the advancement of robotics is that although processing power has come down in price at a rate that no other product ever has, the cost of actuators (The motion inducing components like motors) has remained largely the same. I want to explore an idea I have for using cheaper motors in a robotic arm in another post though.

The problem I want to look at here is the possibility of being able to use cardboard, a material which can almost be considered to have a negative price, as the structure to the robot. I love the ideas of a robot which can produce its own tools from the materials around it. Generally, when I think of this I am thinking of the robot carrying out the carpentry to build itself new limbs or replace damage limbs it has.

The idea spawned from the kickstarted campaign was that it might be possible to use the more ample material of waste cardboard to produce the body of the bot.

Perhaps with restructuring, it might be the material I needed to be able to cheaply produce things that I wanted.

I had been considering getting a 3d printer although the reason behind that was mainly to be able to produce custom gear systems for the robotic design it would also have been useful to use for the body of the robot.

What if I could make use of all the cardboard I had been throwing away.

In my curious googling around the topic, I found this paper which describes the fundamental strength of the cardboard but I wondered what would happen if I experimented with different sized prisms of the material and perhaps even looked into the idea of making cardboard ply with wood glue.

People have made furniture out of cardboard that seems to be strong enough for its purpose.

What I was imagining was taking a prism of cardboard, varying the size of the base triangle, the length of the prism and the number of wraps of cardboard per prism.

I imagine there would be something akin to the following setup to measure what I believe is called the shear strength of the cardboard structure. Here we secure the prism on one side and add weight to the other side measuring the total weight we can add before the beam buckles.

We could then measure the compressive strength using something akin to the following setup although I'm not sure how you would get reliable readings given the prism is likely to fall over with the weight atop. Any support provided to stop it falling over will affect the measurement of the total weight before the beam collapses.

I realise that this post would be much more useful had I actually run the experiment and had numbers to hand. I would counter that with that this blog exists first and foremost for me to explore my ideas prior to or as a replacement for building the projects.

Perhaps I should stick to putting the cardboard in the recycling, rather than leaving a pile in the kitchen for my girlfriend to fall over.

A non-robot use for the cardboard.

I had been considering getting something to vertically grow strawberries in up the window. The plastic solutions on amazon seem to be quite expensive and so I wonder if it would be possible to design a solution using waste cardboard which I could then spray paint to make a more appealing colour. If I could create column I could then either grow the strawberries in plastic bags or old water bottles.

That way I could reuse a lot of the waste and have a custom system that was to spec.

This comment has been removed by a blog administrator.

ReplyDelete